- Turn on the multimeter (volt-ohm meter) and make sure it is set to test direct current, or DC (the V with the solid, not wavy line, next to it), at a range of 20 volts

- Touch the red test lead to the red positive (+) pole on the battery and the black test lead to the black negative (-) pole on the battery

- Record the voltage displayed on the multimeter

- Voltage should be greater than 12.5 volts; if not replace battery

Category Archives: Function

Amp Clamp Meter

- Prior to site visit, determine how many amps the solar panel can push

- At site, set dial to 40 amps

- Toggle button mode to DC

- Clamp around black wire (in DC circuits, black is “hot”) and center vertically

- Press DC zero button

- If taken in full sun, reading should be at or near panel capacity (Ron, are there any hard numbers we could put in here?)

- Make sure to return dial to off position

Solar and Battery

Solar Voltage

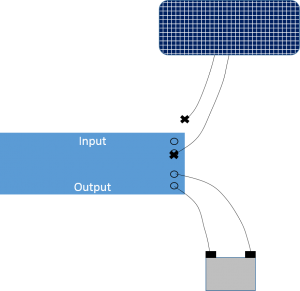

To test solar voltage (voltage coming directly from solar panel), disconnect one lead from the input terminals and place voltmeter probes on the X’s. Reading should be greater than 14 volts. If not, look for loose connections and damaged solar panel.

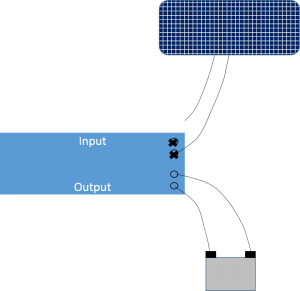

Reverse Voltage

To test reverse voltage (voltage passing through the regulator from the battery), disconnect one lead from the input terminals and place voltmeter probes on the X’s. Reading should be less than 0.20 volts (0.50 volts is marginal). If not, replace solar regulator.

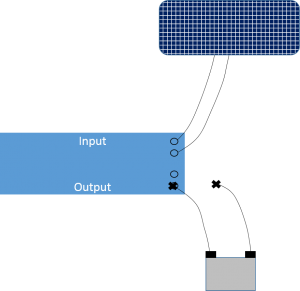

Battery Voltage

To test battery voltage, disconnect one lead from the output terminals and place voltmeter probes on the X’s. Reading should be greater than 12.5 volts. If not, replace battery.

Charging Voltage

To test charging voltage (voltage coming through regulator), disconnect one lead from the output terminals and place voltmeter probes on the X’s. If the voltage is greater than 14 volts, replace solar regulator.

Make sure all leads are reconnected to appropriate terminals when finished.

Stevens Shark – Download Data

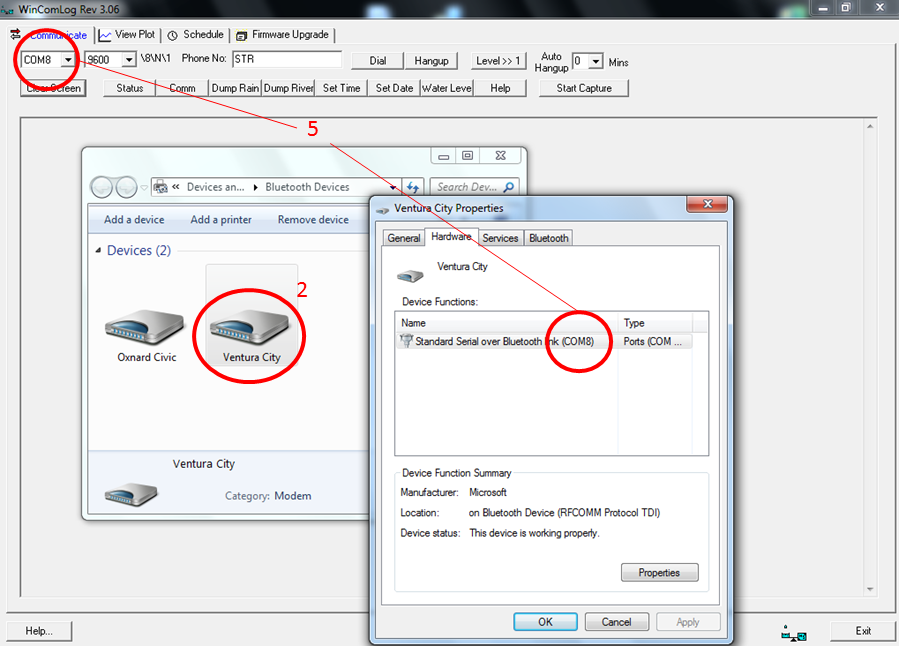

- Turn on Bluetooth capability (procedure will vary by laptop)

- Click on appropriate site from list

- If site does not automatically connect, use the password 1610

- Open WinComLog

- Select correct COM port

- Follow standard directions for downloading data from the ML1 here

Standard Rainfall Gauge – Maintenance

- Remove funnel from top of can and clean all dirt and debris

- Locate measuring mark on side of can; if no mark present, use the seam of the can

- Measure distance to oil surface from rim of can

- Record distance in yellow field book and subtract from previous visit to determine depth of rainfall

- If oil cap has turned white/milky:

- Pump material into “ook” container

- Add 1” of oil to can

- Measure new distance to water surface and record value in yellow field book

- Replace funnel on top of cap

Hydrological Services TB3 – Maintenance

This is the tipping rainfall bucket used at most rain gauge sites. Field maintenance is often performed concomitantly with data downloads, so please refer to this when servicing TB3 units.

Cleaning

- Loosen three screws at bottom of TB3 and remove circular enclosure

- Clean funnel and enclosure using paintbrush and/or damp rag

- Turn enclosure over an unscrew syphon

- Apply grease to syphon O-ring, if necessary

- Remove and clean filter screen

- Reassemble filter screen and syphon, hand-tighten back on to enclosure

- Remove debris and clean bucket assembly

- Verify base is level by utilizing bullseye levels

- Reattach enclosure and tighten 3 screws at bottom of TB3

Annual Maintenance

To decrease the likelihood of lost data, the 3.6V battery in ML1s must be changed each year during annual maintenance runs. Also, rain gages must be calibrated each year.

Dynamic Test

Prior to this dynamic test, disconnect TB3 from the terminal block (preferred) or from the transmitter. After the test is complete, make sure to reattach TB3 and confirm tips via website.

- Download data and clear ML1

- Place funnel back on top of TB3

- Set tripod on top of funnel

- Fill calibration cylinder until meniscus forms on top

- Screw on 100 mL nozzle taking care not to spill water

- Set on tripod, open valve and wait for water to drain out of bottle

- Target is 82 tips, but a range of 78-86 (5%) is acceptable

- Download data into calibration file and clear ML1 again

- If number of tips is out of range, perform static calibration below

Static Calibration

- Fill syringe with 10 mL of water

- Slowly add water to bucket on one side of TB3

- When bucket tips, record volume expelled from syringe

- Target is 6.8 mL, but a range of 6.46 – 7.14 mL (5%) is acceptable

- Repeat calibration on other side

- Use set screws underneath each bucket to increase or decrease the amount of water needed to tip the bucket

- Once calibrated, perform dynamic test (above) again

High Sierra 3206 – Transfer Data

High Sierra 3206 – Download Data

WaterLOG H-350XL/H-500XL – Transfer Data

Stream data downloaded from equipment in the field should ideally be transferred immediately from temporary media (e.g., USB key) to a folder on the laptop, and should be stored in the SiteMonthDayYear format (e.g., 800a080615).

- Locate appropriate file on laptop and transfer to station folder on network drive (e.g., Q:\STATIONS\TL\800A\2015\Misc)

- Open Hydstra and select from the menu tree: Programs by Function > Hydstra/TS – Time Series > Hydstra Data Management > HYDMWB – Data Managers Workbench.

- Press the Open folder icon or select File > Open

- In the Open Time Series Sites dialog box that opens, enter the site number in general format (e.g., 800) and click the Lookup Site button

- Select the specific site (e.g., 800A) that appears in the dialog box and then press OK

- Press OK in the Open Time Series dialog box

- Single-click the site icon that has an A at the end (e.g., 800A A) and the select File > Copy

- In the Select Work File dialog box that opens, Select B as the New DataSource and then press OK; a new file icon is placed on the workbench (e.g., 800A B)

- Select File > Import Data and navigate to appropriate file on the network drive, as described in step 1, and then press Open

- Press Finish in the Import Data dialog box and close the event log that appears in Hydstra Explorer; a new file icon is placed on the workbench (e.g., 800A C)

- Drag the C file to the B file and release

- In the dialog box, select the Resolve Overlaps: Split blocks if necessary, preserving the C file radio button and press OK

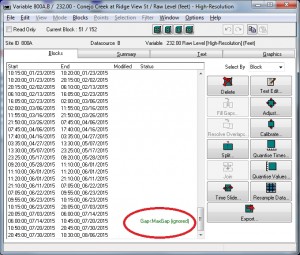

- Double-click the B file to open the Work File dialog box (the end date of the 232.00 variable should be modified to match the date and time of the site visit)

- Double-click variable 232.00, which will open the High-Resolution data set

- Most of the time, Gap<MaxGap (ignored) will be displayed between the previous data set and the data set most recently imported

- To eliminate this gap, select the block of data immediately below this status and select Split

- In the Split Block dialog box, add five minutes to Split Time (e.g., 10:50:00_07/20/2015 becomes 10:55:00_07/20/2015) and press OK; this will create an additional block of time

- Select the new block and the one immediately above it (this should be the one that has the Gap<MaxGap (ignored) status) by shift-clicking both

- Select Fill Gaps and from the dialog box that opens, select the Extend Backwards (add a new point to the start of the second block) radio button and 1 Good Unedited Data from the Inserted Quality dropdown; press OK

- A new block is created which spans the existing blocks; both the new block and the block below now display Yes in the Modified column

- Close the dialog box and press Yes to save your changes and then close the Work File dialog box

- Finally, drag the B file to the A file and select the Merge (preserve B File data if duplicates) radio button, making sure the Delete B File option is checked

- Press OK and close event log that appears in Hydstra Explorer

WaterLOG H-350XL/H-500XL – Download Data

Gage height and discharge data are periodically transferred from the unit in the form of a .NEW file. After being copied to the appropriate media, the .NEW file is deleted, thereby reducing file size for subsequent downloads. Should problems arise in downloading this file, a longer term record (.WRP file) is stored on the unit and can be accessed in a similar manner. Unlike the .NEW file, the .WRP file is only deleted at the end of each water year.

The processes described below is applicable to several types of transfer media, including USB keys or PCMCIA (Flashdisk) cards

Copy .NEW File to Media

- Open lid of H-350XL/H-500XL

- Insert PCMCIA card or USB key into appropriate slot

- Press Display On/Off key to turn on display

- Stage = x.xx is displayed; record this value on front sheet

- Press ▼ key until System Status is displayed

- Press ► key, Battery = xx.xx volts is displayed

- Press ▼ key, Min Battery = xx.x is displayed

- Press ▼ key, Max Battery = xx.x is displayed

- Press ▼ key, System Resets = x is displayed

- Press ▼ key, Resets Stats Screen? is displayed

- Press Enter to reset stats

- Press ◄ key to get back to System Status screen

- Press ▲ key until Data Options is displayed

- Press ► key, Data Memory OK is displayed

- Press ▼ key until Copy Files is displayed

- Press ► key, Copy All 2 Ext Card? is displayed

- Press ▼ key until Copy .NEW to USB or Copy .NEW to Card is displayed

- Press Enter, Copying [site].NEW is displayed

- When copying is completed, Enter to Erase .NEW is displayed

- Press Enter, Erasing .NEW is displayed

- Press Esc until Stage = x.xx is displayed

- Remove PCMCIA card or USB key

- Press Display On/Off key to turn off display

- Verify that Scanning is On is displayed

Copy .WRP File to Media

- Open lid of H-350XL/H-500XL

- Insert PCMCIA card or USB key into appropriate slot

- Press Display On/Off key to turn on display

- Wait a few seconds and the instrument should give a gage height reading

- Press

- Push ▼ key until Data Options is displayed

- Push ► key, Data Memory OK is displayed

- Push ▼ key until Copy .WRP to Card or is displayed

- Push Enter, unit should display the file that is being copied

- When the copying is complete, Done, Press Any Key is displayed

- ERASE NEW FILE

- Remove the PCMCIA card or USB key

- Push Display On/Off to turn off display

Clear Internal Memory

This process should be done on a yearly basis on the first download after the start of the new water year if the data for the previous water year is known to be complete. Be sure to download .NEW and .WRP files before completing this process.

- Open lid of H-350XL/H-500XL

- Insert PCMCIA card or USB key into appropriate slot

- Press Display On/Off key to turn on display

- Wait a few seconds and the instrument should give a gage height reading

- The scanning must be turned off in order to clear the memory not the logging

- Press the Esc key until back to Data Options

- Arrow Down to Scan Setup

- Right Arrow, Scanning [ON] should now be displayed

- Press Enter and ON should now be flashing

- Press ▲ key to turn the scanning off, then press Enter

- Press the Esc key until back to Scan Setup

- Press ▲ key until Data Options is diplayed

- Press ► key, Data Memory OK should now be displayed

- Press ▼ key until Erase Internal Data is displayed, then press Enter

- When asked Are You Sure?, press Enter

- Press the Esc key until back to Data Options

- Press ▼ key until Scan Setup is displayed

- Press ► key, Scanning [OFF] should now be displayed

- Press Enter and OFF should now be flashing

- Press ▼ key to turn the scanning on, then press Enter

- Press the Esc key until back to Scan Setup

- Press ▲ key to Sensor Input Setup

- Press ► key, Stage Setup should now be displayed

- Push Display On/Off to turn off display